The Purpose of Heat Treating

The objective of heat treating is to achieve specific characteristics in the final product, such as:

- Hardness:Enhancing the material's resistance to wear and tear.

- Strength:Increasing the material's ability to withstand stress without breaking.

- Toughness:Improving the material's capacity to absorb energy before fracturing.

- Ductility:Making the material more flexible and able to be stretched or deformed without breaking.

- Elasticity:Granting the material increased springiness, allowing it to return to its original shape after deformation.

Key Aspects of Heat Treating

Heat treating involves three main stages:

- Heating:The material is gradually heated to a predetermined temperature, which depends on the desired outcome and the material's properties.

- Holding:The material is held at that temperature for a controlled amount of time to enable the internal structural changes to occur.

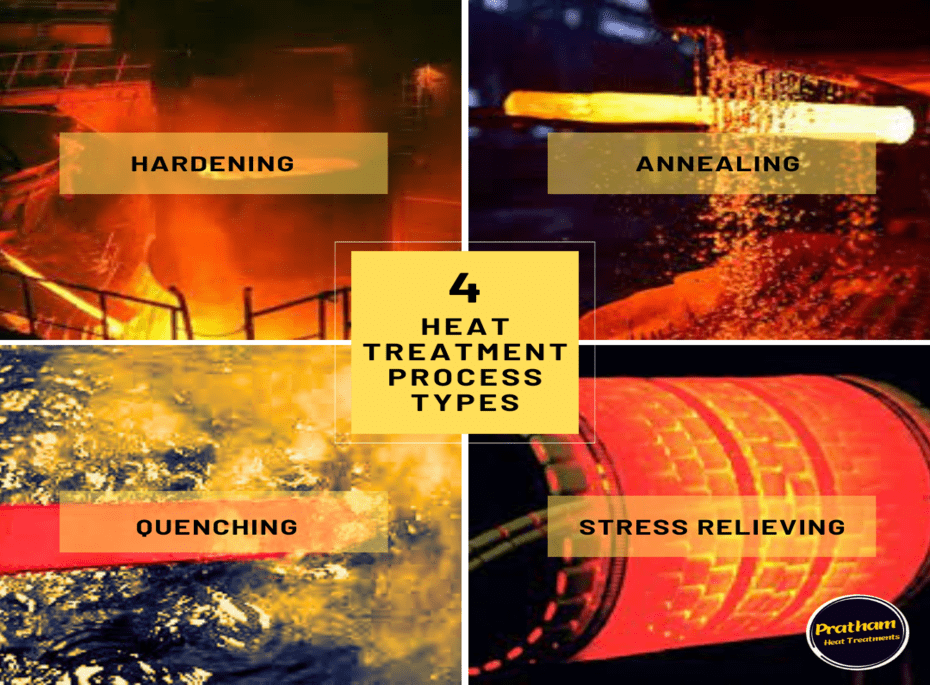

- Cooling:The material is then cooled at a specific rate, which can be rapid (quenching) or slow (air cooling). This cooling rate significantly impacts the final properties of the material.

By manipulating these heating and cooling stages, heat treatment allows engineers to achieve a vast array of properties in various materials. This versatility makes heat treating an essential process in numerous industries, including construction, automotive, aerospace, and medical equipment manufacturing.